Polycoat™ Waterborne epoxy resin and waterborne curing agent are developed and manufactured by Lingwe. Polycoat™ has excellent chemical resistance and salt spray resistance, and is suitable for anti-corrosion protection of automotive parts such as axle and drive shaft.

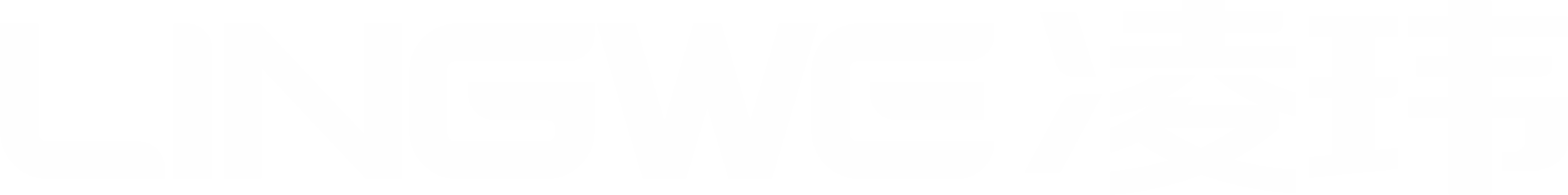

WBH522 waterborne epoxy emulsion and WBH816 waterborne curing agent combination with excellent special substrate adhesion, can be widely used in aluminum substrate, galvanized, stainless steel, hot rolled steel, electrophoretic plate and other metal surface (only need to remove oil, no grinding), providing excellent salt spray resistance and fast drying speed, while cost-effective.

In addition, the combination also has a high gloss, as well as excellent chemical resistance, making it an ideal choice for integrated coating of automotive parts.

- Experimental test: high light black paint salt spray

○ Single bottom 60μm film thickness, cold rolled steel grinding.

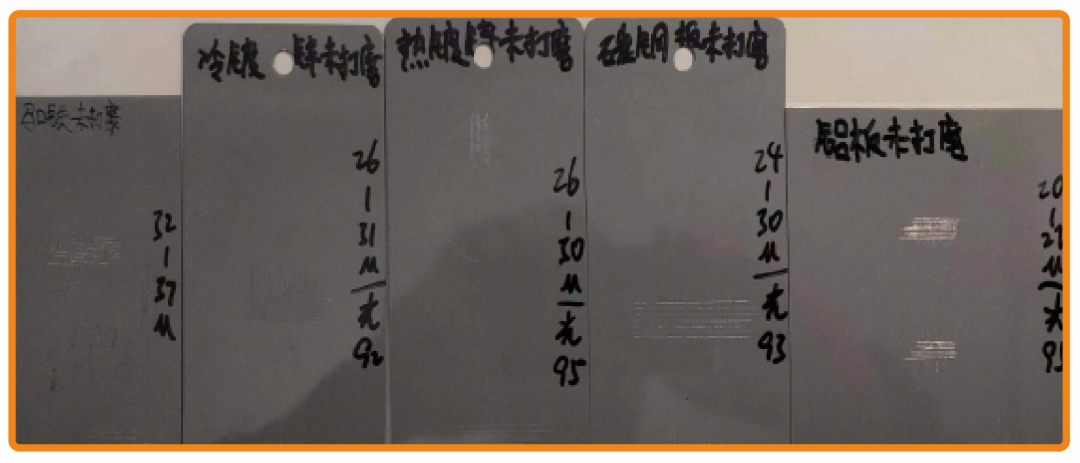

○ 500 hours salt spray and gloss.

○ 500 hours salt spray and gloss.

中文

中文